| Apr 24, 2024 |

|

(Nanowerk News) Dr. Han Joong Tark and student researcher Lee Do Geun at the Nano Hybrid Technology Research Center of Korea Electrotechnology Research Institute (KERI) have developed a new manufacturing technique for silicon/nitrogen-doped carbon composite anode materials. These materials aim to enhance the capacity and stability of lithium-ion battery anodes.

|

|

Silicon, despite offering significantly higher energy density compared to graphite (a common anode material), suffers from a major drawback: it expands 3-4 times during charging and discharging, leading to performance degradation. To address this issue, researchers are blending silicon with graphite to balance their strengths and weaknesses.

|

|

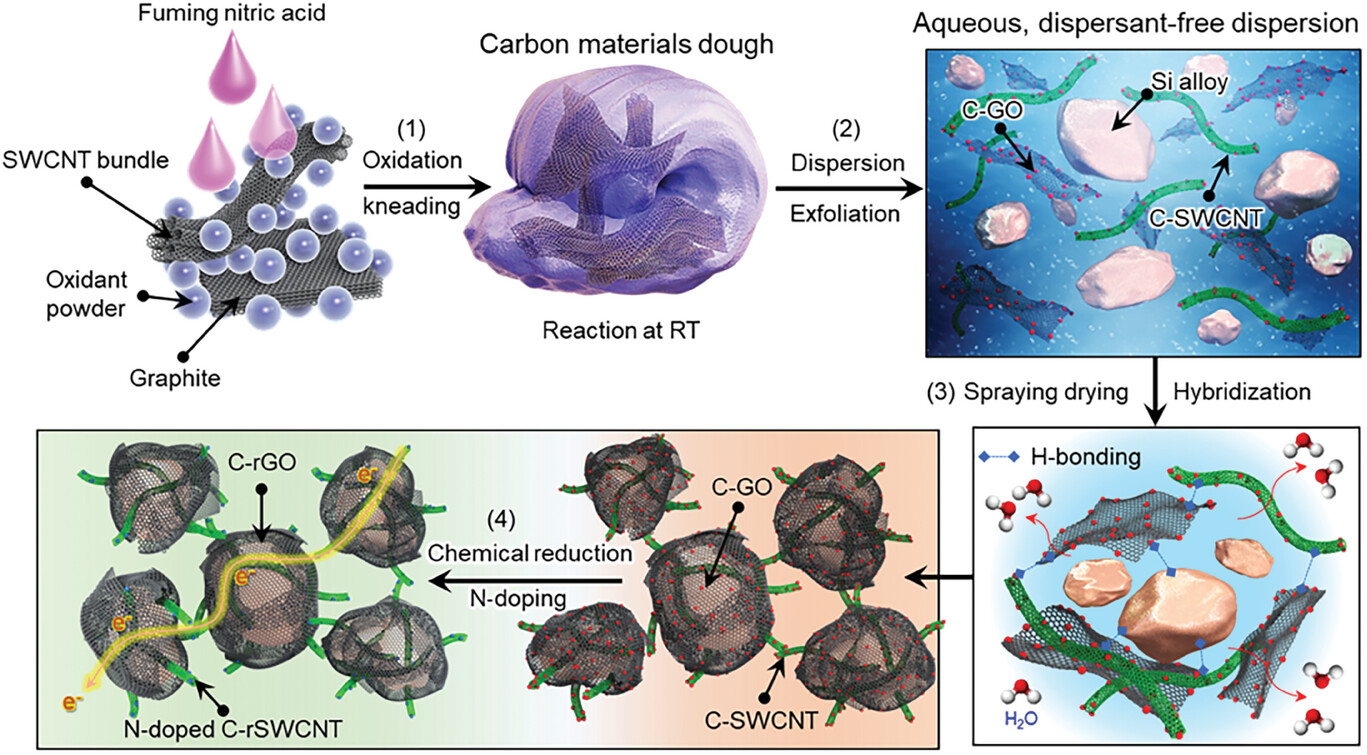

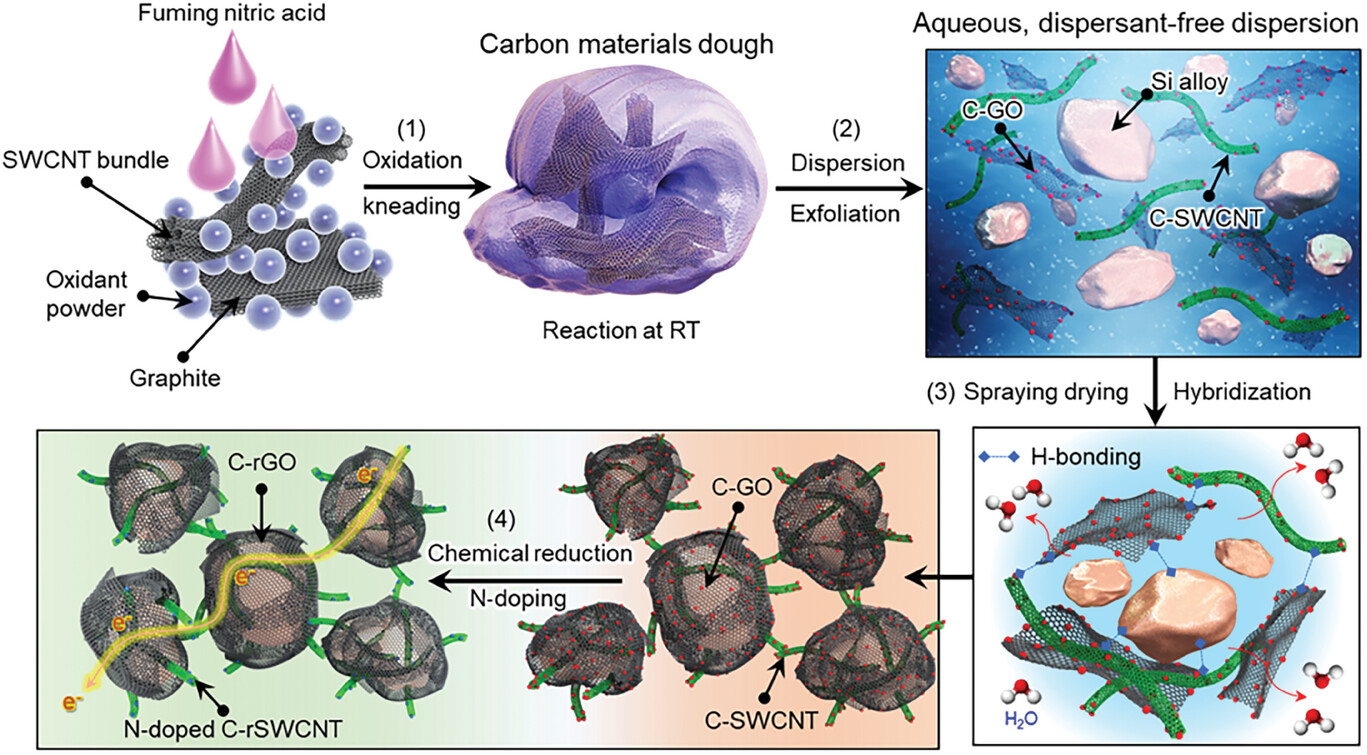

To maximize silicon content and overcome its limitations, KERI has utilized nitrogen-doped single-walled carbon nanotubes and graphene. Single-walled carbon nanotubes, being thinner and more conductive than multi-walled ones, present challenges in dispersion due to their small diameter. Leveraging their expertise in nanocarbon materials, KERI has developed a pioneering functionalization and colloidal dispersion technologies, facilitating the incorporation of nitrogen onto the carbon nanotube surface.

|

|

| Schematic diagram of SiA/nanocarbon (NC) composite powder preparation process. 1) Highly efficient oxidation of single-walled carbon nanotubes (SWCNTs) and graphite through chlorate-based oxidation by kneading, 2) exfoliation of graphite oxide into graphene oxide (GO) and dispersion of C-SWCNTs without dispersants, 3) Hydrogen bonding driven hybridization of SiA with oxidized NC through spray drying, (4) chemical reduction of SiA/NC composite powder using hydrazine. (Image: Reprinted from DOI:, CC BY)

|

|

When applied to lithium-ion battery anodes, these nitrogen-doped single-walled carbon nanotubes accelerate lithium-ion movement to silicon, enhancing charging speed and stability across numerous charge/discharge cycles. Additionally, encapsulating the anode materials with graphene further stabilizes silicon expansion.

|

|

Through extensive testing, KERI has demonstrated that batteries utilizing their composite anode materials maintain over 82% performance after 100 charge/discharge cycles, compared to only 30% for conventional silicon composite anodes. This advancement eliminates the need for conventional conductive additives like carbon black.

|

|

The team envisions broader applications for this technology, including solid-state batteries, where lithium diffusion speed is critical. The research findings have been published in the journal Advanced Functional Materials (“Dispersant‐Free Colloidal and Interfacial Engineering of Si‐Nanocarbon Hybrid Anode Materials for High‐Performance Li‐Ion Batteries”).

|

|

KERI has completed full-cell evaluations and patent applications for their composite anode materials, expecting strong interest from companies seeking high-capacity lithium-ion batteries. They are poised to identify potential partners for technology transfer.

|